I’ve been writing about the real benefits of the real technology DigitalGlobe brings to its customers, but haven’t spent much time talking about the broader technology trends in the industry. In this blog, I’m briefly breaking with tradition to comment on the “New Space” (or “Space 2.0”) phenomenon and what it means for our industry.

New Space is an approach to developing commercial space systems faster and cheaper than ever before, and the thesis behind New Space is very Silicon Valley. Companies building satellites in this way generally follow a few key principles: Leverage the incredible pace of advancements in electronics. Rapidly build and launch successive generations of spacecraft that are each more capable than the last. Use commercial technology that is more affordable than traditional space-qualified components. Pack it into smaller satellites and launch them as hitchhiker payloads, saving on launch costs.

Some applications can benefit tremendously from the New Space approach: making weather measurements (GPS radio occultation), tracking large ships globally (AIS), packet radio communications from the industrial Internet of Things (shipping containers, trucks, railcars), and low-resolution, broad-area imaging. Even defense applications can benefit from this approach; I started my career nearly 30 years ago on “Brilliant Pebbles,” which was part of the Strategic Defense Initiative and some would argue the ancestor of today’s New Space projects. Note the familiar themes found throughout this 1989 New York Times article on the program, which begins:

“Rapid advances in the miniaturization of parts for high-technology weapons have allowed the Pentagon to give its ''Star Wars'' anti-missile program a major new emphasis. Instead of focusing exclusively on big, bulky, costly weapons, it would now create swarms of small, cheap, brainy rockets to hurl at enemy missiles with deadly accuracy.”

Space technology has come a long way since Brilliant Pebbles. It has reduced the cost of many spacecraft electronic components, and will continue to do so. However, the most foundational aspect of satellite imaging—physics—remains unchanged. So for the commercial earth observation industry, there are several myths of the New Space story that, despite the hype, don’t hold up to scrutiny. Let’s explore a couple of them.

Myth: Leveraging agile methodologies, it’s faster and cheaper to build and launch successive generations of hardware to see if they work, even if that results in a series of failures.

Well, this was the way that the space industry got its start with many early rocket failures, when nobody knew what would or wouldn’t work. It got us to where we are today with SpaceX’s incredible rocket landings. The integrated circuit industry had a similar start: build a chip, see if it works, learn why it doesn’t, and then iterate. But this approach was expensive. Failed hardware doesn’t produce revenue or meet customer needs. And going through the entire build process takes time, so the iteration rate is limited.

Both the electronics and aerospace industries learned that there was a better way that was both more cost effective and offered faster cycle times. Simulate where you can; software tools iterate far faster than building hardware. When simulation won’t do, test at the earliest possible stage to fail fast, versus discovering a mistake at the end. And use reprogrammable software (vs. inflexible hardware) so that if you do make a mistake, it is easy and quick to fix.

The approach of building successive generations of experimental hardware to see if they work is fine as a teaching exercise for budding aerospace engineers. It even has an acceptable role in R&D, if testing on orbit is the only possible way to validate a new technology. But it’s not a way to run a business. As an industry, we’ve learned that “ready, aim, fire” works better than “spray and pray.”

Myth: Moore’s Law dictates that improvements in the size, weight, power, and cost of electronics automatically translate into improvements in capability for satellites.

On the one hand, this is true: modern electronics have already dramatically improved the sophistication of satellites’ onboard processors, software controlled radios, and data storage. These continuing improvements contribute to reducing capital costs for satellite subsystems. On the other hand, the overall benefits that these technology improvements can deliver are dependent on how much of a satellite’s size, weight, power or performance are driven by them.

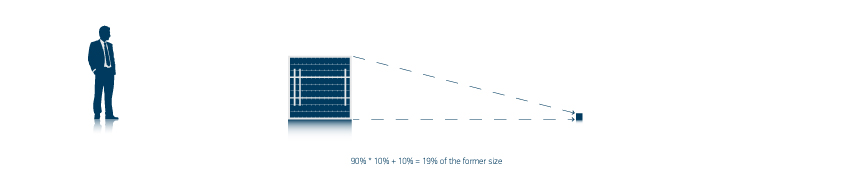

In a softball-sized cubesat, virtually all of the spacecraft is made up of electronics. There are no large telescopes, radio dishes, fuel tanks, or maneuvering devices. Perhaps 90% of the satellite’s size benefits from electronics miniaturization. If you can pack the electronics into 10% of its former size, this means that your satellite can be shrunk by nearly a factor of five (90% * 10% + 10% = 19% of the former size).

I’ve been writing about the real benefits of the real technology DigitalGlobe brings to its customers, but haven’t spent much time talking about the broader technology trends in the industry. In this blog, I’m briefly breaking with tradition to comment on the “New Space” (or “Space 2.0”) phenomenon and what it means for our industry.

New Space is an approach to developing commercial space systems faster and cheaper than ever before, and the thesis behind New Space is very Silicon Valley. Companies building satellites in this way generally follow a few key principles: Leverage the incredible pace of advancements in electronics. Rapidly build and launch successive generations of spacecraft that are each more capable than the last. Use commercial technology that is more affordable than traditional space-qualified components. Pack it into smaller satellites and launch them as hitchhiker payloads, saving on launch costs.

Some applications can benefit tremendously from the New Space approach: making weather measurements (GPS radio occultation), tracking large ships globally (AIS), packet radio communications from the industrial Internet of Things (shipping containers, trucks, railcars), and low-resolution, broad-area imaging. Even defense applications can benefit from this approach; I started my career nearly 30 years ago on “Brilliant Pebbles,” which was part of the Strategic Defense Initiative and some would argue the ancestor of today’s New Space projects. Note the familiar themes found throughout this 1989 New York Times article on the program, which begins:

“Rapid advances in the miniaturization of parts for high-technology weapons have allowed the Pentagon to give its ''Star Wars'' anti-missile program a major new emphasis. Instead of focusing exclusively on big, bulky, costly weapons, it would now create swarms of small, cheap, brainy rockets to hurl at enemy missiles with deadly accuracy.”

Space technology has come a long way since Brilliant Pebbles. It has reduced the cost of many spacecraft electronic components, and will continue to do so. However, the most foundational aspect of satellite imaging—physics—remains unchanged. So for the commercial earth observation industry, there are several myths of the New Space story that, despite the hype, don’t hold up to scrutiny. Let’s explore a couple of them.

Myth: Leveraging agile methodologies, it’s faster and cheaper to build and launch successive generations of hardware to see if they work, even if that results in a series of failures.

Well, this was the way that the space industry got its start with many early rocket failures, when nobody knew what would or wouldn’t work. It got us to where we are today with SpaceX’s incredible rocket landings. The integrated circuit industry had a similar start: build a chip, see if it works, learn why it doesn’t, and then iterate. But this approach was expensive. Failed hardware doesn’t produce revenue or meet customer needs. And going through the entire build process takes time, so the iteration rate is limited.

Both the electronics and aerospace industries learned that there was a better way that was both more cost effective and offered faster cycle times. Simulate where you can; software tools iterate far faster than building hardware. When simulation won’t do, test at the earliest possible stage to fail fast, versus discovering a mistake at the end. And use reprogrammable software (vs. inflexible hardware) so that if you do make a mistake, it is easy and quick to fix.

The approach of building successive generations of experimental hardware to see if they work is fine as a teaching exercise for budding aerospace engineers. It even has an acceptable role in R&D, if testing on orbit is the only possible way to validate a new technology. But it’s not a way to run a business. As an industry, we’ve learned that “ready, aim, fire” works better than “spray and pray.”

Myth: Moore’s Law dictates that improvements in the size, weight, power, and cost of electronics automatically translate into improvements in capability for satellites.

On the one hand, this is true: modern electronics have already dramatically improved the sophistication of satellites’ onboard processors, software controlled radios, and data storage. These continuing improvements contribute to reducing capital costs for satellite subsystems. On the other hand, the overall benefits that these technology improvements can deliver are dependent on how much of a satellite’s size, weight, power or performance are driven by them.

In a softball-sized cubesat, virtually all of the spacecraft is made up of electronics. There are no large telescopes, radio dishes, fuel tanks, or maneuvering devices. Perhaps 90% of the satellite’s size benefits from electronics miniaturization. If you can pack the electronics into 10% of its former size, this means that your satellite can be shrunk by nearly a factor of five (90% * 10% + 10% = 19% of the former size).

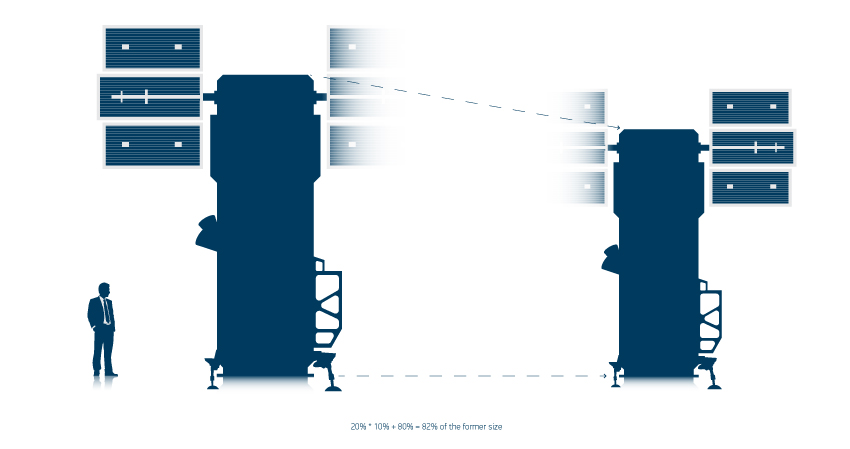

But for DigitalGlobe’s imaging satellites, for which physics requires the utilization of large telescopes to achieve high resolution, large fuel tanks for long on-orbit lifetimes, and large control-moment gyros for agility, the electronics account for ~20% of the satellite. By this same math, reducing the electronics to 10% of their former size would reduce the total size of the satellite by only 18% (20% * 10% + 80% = 82% of the former size).

Now, this is not to say that it’s not worth leveraging advances in electronics. We have been doing so for years at DigitalGlobe; faster electronics helped improve our collection capacity by tenfold between our first-generation QuickBird satellite and the current-generation WorldView satellites. But for the high resolution that our customers need to be able to make decisions with confidence, size matters, and our satellites have also evolved to feature the large telescopes needed to extend our industry lead in resolution.

Webcomic courtesy of xkcd.com

So what is true about New Space?

As I’ve said in previous blog posts, for every job there is a proper tool, and the right combination of tools can be very powerful. We believe smaller satellites can be highly complementary to large ones for applications such as for tipping and cueing, evidenced by our partnership to build small yet very capable satellites for certain high-revisit applications. We believe that advancements in electronics can continue to lower the cost of satellites of any size, small or large. And we believe that more highly integrated electronics can simplify supply chains and reduce the time it takes to build satellites, improving time to market. Software programmability further reduces build times and improves on-orbit flexibility.

New satellite business ideas have attracted a tremendous amount of attention and investment in recent years. Our hope is that this growing community will give credence to the many hard-learned lessons and immutable truths that our industry is built upon, and not promise more than they can hope to deliver.

To learn more about DigitalGlobe’s approach to building satellites, read the “Real Technology, Real Benefits” blog series.

Part 1: pointing agility

Part 2: revisit rate & collection capacity

Part 3: image quality

Part 4: multi-source applications

Webcomic courtesy of xkcd.com

So what is true about New Space?

As I’ve said in previous blog posts, for every job there is a proper tool, and the right combination of tools can be very powerful. We believe smaller satellites can be highly complementary to large ones for applications such as for tipping and cueing, evidenced by our partnership to build small yet very capable satellites for certain high-revisit applications. We believe that advancements in electronics can continue to lower the cost of satellites of any size, small or large. And we believe that more highly integrated electronics can simplify supply chains and reduce the time it takes to build satellites, improving time to market. Software programmability further reduces build times and improves on-orbit flexibility.

New satellite business ideas have attracted a tremendous amount of attention and investment in recent years. Our hope is that this growing community will give credence to the many hard-learned lessons and immutable truths that our industry is built upon, and not promise more than they can hope to deliver.

To learn more about DigitalGlobe’s approach to building satellites, read the “Real Technology, Real Benefits” blog series.

Part 1: pointing agility

Part 2: revisit rate & collection capacity

Part 3: image quality

Part 4: multi-source applications